Supply chain resilience, the new paradigm in a post-Covid world

In the past, global companies aiming for operational excellence focused on optimizing their supply chain. With lean concepts in mind, the main priorities of operations departments were to reach markets in the most efficient way and at a reduced cost. I’m now seeing companies starting to focus on the importance of having an agile supply chain to deal with external factors such as labor cost changes, rising protectionism and associated tariffs. However, Covid-19 forced companies to reassess their long-term strategy.

Plant lockdowns and supplier shortages are events that companies are not used to experiencing simultaneously. Some companies realized that there were major structural flaws in their supply chain: footprint issues, global sourcing or lack of supply chain digitization. These organizations now include a new paradigm in their long-term operations strategy: resilience. We have summarized the research carried out on resilience strategy by institutions such as BCG, Gartner or McKinsey.

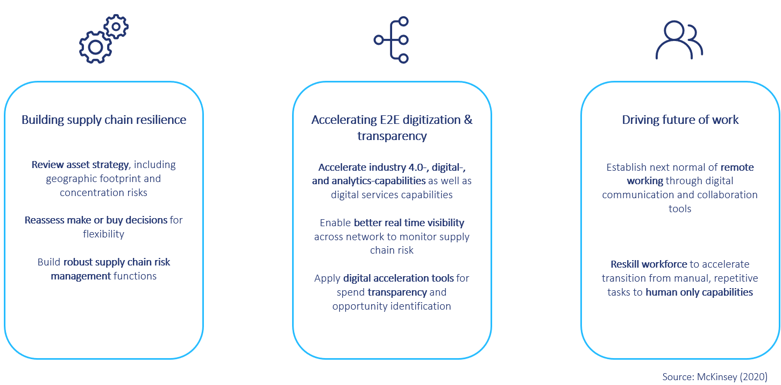

To embrace the post-Covid-19 world successfully, company leaders will need to incorporate three main strategies in their operations vision: building supply chain resilience, accelerating end-to-end digitization and driving the future of work.

Building supply chain resilience

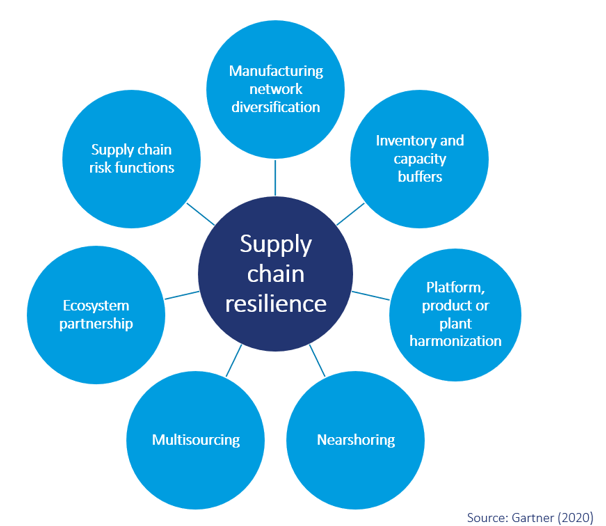

The strategy to build supply chain resilience can be set out in seven pillars, as shown in the graph below. We shall explain the main strategies we have identified.

First, it is primordial for companies to diversify their manufacturing or sourcing bases whenever possible in order to avoid supply disruptions. Multinational corporations are switching from a global supply chain strategy to a more regional approach to improve their local footprint, which allows for a higher degree of flexibility. It will incur costs that should be considered as costs of doing business rather than inefficiency. Having a buffer capacity in the form of underutilized production or excessive stock is a second option for dealing with daily disruption challenges.

Another way companies bring resilience into their operations is by harmonization. Standardizing components across multiple products or using common platforms will reduce supply chain complexity while incorporating extra flexibility. Introducing new suppliers will reduce the risk of supply disruptions. Relying on suppliers having multiple manufacturing locations may be an essential advantage. Considering their raw materials suppliers and service providers as real partners will be key for a long-term collaboration. Close partners are more likely to support each other in the event of a crisis.

Accelerating end-to-end digitization

Supply chain digitization is also a key aspect when preparing organizations for future externally driven supply challenges. Companies need to focus on mapping out the areas of disruptions along their value chains. By digitizing their value chains, companies will be able to identify these disruption sources in order to mitigate their effects. Visibility is key.

One way to increase visibility across a company’s value chains is to build reports and dashboards based on key metrics. Companies that have invested in analytics-driven technologies could easily map out the major operating costs in times of crisis. For instance, the best strategies regarding inventory rebalancing activities or optimizing transportation lanes could be easily analyzed, and fast decisions could be made accordingly.

The second step is to design an end-to-end supply chain control tower. It enables organizations to stop spending endless resources on firefighting symptoms and instead allows them to focus on root cause analysis. Control towers incorporate contingency plans and suggest optimal BCP per supply challenges causes. It also allows companies to speed up decision-making processes and act proactively.

Driving the future of work

The Covid-19 pandemic has had an impact on the way employees work. Remote working has become the new normal. Companies with ready-to-use digital tools and a robust IT infrastructure in place were able to adapt quickly to this new way of working. A strong mindset switch was required to ensure the decoupling of business continuity and productivity from a physical on-site presence.

The operator of the future will play a key role in tomorrow’s resilient operations environment. Well-trained operators will perform more and more tasks requiring skills such as reasoning, planning, or problem-solving, which will replace repetitive work. A workforce with cross-functional and job-switching capabilities will bring more flexibility and agility in the event of a crisis.

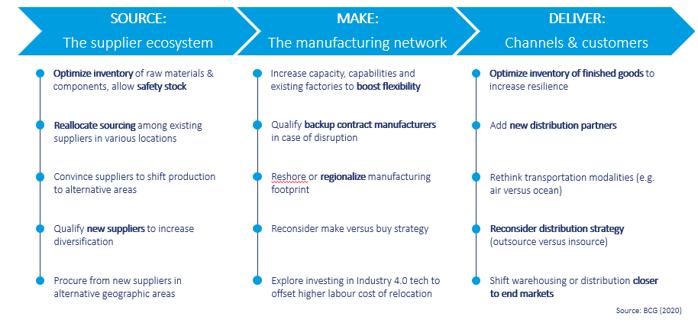

Impact on end-to-end supply chain

Building resilience at each step of the value chain will help companies to achieve a more robust network. At the source of the value chain, the key message is diversification. Supply shortage risks will be reduced by allowing sourcing from various locations and qualifying new suppliers with geographical spread. Creating safety stock for raw materials and finished goods will also help mitigate risks at the source.

The manufacturing network can also be strengthened by creating more flexibility. Enabling products to be manufactured in unusual production sites (internal or external) or regionalizing the production footprint are examples of how to boost an organization’s flexibility.

Reinforcing the delivery network against external issues is also important. Having more distribution points in various locations (and closer to markets when possible) or optimizing finished goods inventories will help companies face delivery challenges. Improving the distribution channel reliability will enable them to reach out to customers more consistently, which will improve client satisfaction.

The Covid-19 impact has changed the vision most organizations have of long-term supply chain strategies. New KPIs measuring resilience, flexibility and agility will play a key role in the future. These new aspects will, of course, have to be fully integrated into the pre-Covid operational excellence vision.

At Bluecrux, we are helping companies to integrate this new resilience paradigm as part of their supply chain vision, in order to build a more robust and flexible network. It is crucial for our customers to be ready for the next supply crisis.

Feel free to get in touch for more details!

Arnoud is a supply chain and operations professional.