Planning in the digital age: Let data do the dirty work!

In digital age planning, for which “customer centricity” is king and “real-time data” is queen, you cannot afford to continue allowing historical data dictate your decisions. I think it’s time for you to let the data do the dirty work and get your brain cracking on scenarios and—ultimately—your strategy!

It’s perfectly understandable to use past experience as our best guide to predictions about the future. Our brains are programmed that way. It’s how our species emerged and evolved. So, yes, what worked last year may well work next year. But it’s almost just as likely NOT to work next year.

The world is changing fast. And I see how quickly supply chain planning is changing, too. Sure, many things will never change. But some pretty important things already have—like data and smart algorithms.

Decision-makers in innovative companies and industries know what value they can get from comparing and analyzing different end-to-end financial scenarios. They use relevant and reliable data for making decisions. Dynamic master data based on transactional data (ERP, MES, OEE, etc.) feeds modern planning tools to allow analysis, forecasting and scenario simulation.

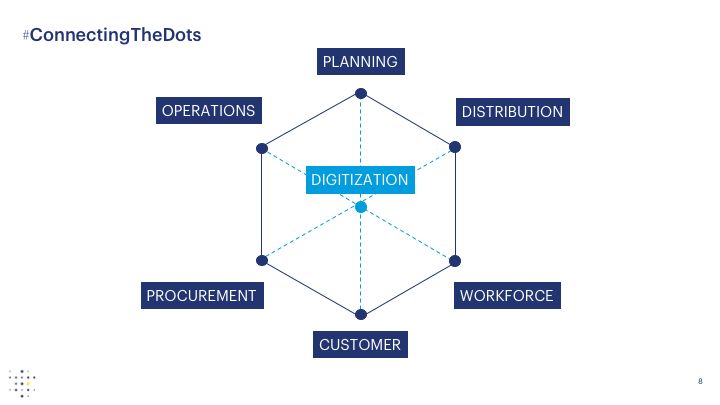

→ Companies determine the optimal customer/product/source mix by “connecting the dots” in a smart way (customers, sales, operations, finance, suppliers, partners, etc.).

Most important steps to get value from your data.

Step 1: Shine a light on your end-to-end supply chain

From suppliers, raw materials and finished products through to your customer. It sounds logical. But in reality, our current end-to-end supply chains are no longer linear but interconnected. Product flows change regularly. It’s hard to find a single person or department that knows all the ins and outs of your end-to-end supply chain. Move one step beyond, and you will discover that your transactional systems (ERP, MES, etc.) hold the reality of your supply chain.

By connecting this data, you can create a digital twin of your end-to-end supply chain. With the current modern tools based on big data, machine learning and artificial intelligence, this digital twin can be updated daily, weekly or as often as you wish. Unlocking this data potential will also provide end-to-end supply chain visibility.

Step 2: Switch to integrated business planning that works with financial scenarios

Over the years, sales and operations planning (S&OP) has greatly improved the efficiency and profitability of supply chains in virtually every sector. The next logical step is integrated business planning (IBP) that seeks to involve a wide range of business stakeholders to make true forward-looking business decisions based on financial scenarios.

Step 3: Plan with the lights out, thanks to the right tool

To make digital-age planning work, you need a tool that lets you “play” with your data. In practice, this means that your planning tool:

- Manages exceptions.

- Provides support for scenario analysis and different aggregation levels.

- Allows chain partners and parties to upload data to cloud software.

- Returns dynamic supply planning parameters for the various planning systems. These systems deal with operational lead times, batch size, production line, capacities, production time, stock control, scrap rate/control, temperature control, energy use, production efficiency, etc.

Based on years of experience with projects addressing different aspects of supply chain and operations in various sectors, we at Bluecrux see the supply chain future.

Discover more about data mining with a digital supply chain twin:

> The role of AI and ML in data harmonization

> How to analyze material flows using process mining techniques